The Highway to a Sustainable Livelihood

January 31, 2017

Improving Access to clean water for all

February 6, 2017

.

Graphene- The Tougest Innovation in Town

One of the most sought after resource, scientists team(CSIRO) discover a breakthrough in ecologically friendly and sustainable commercial production, that can mark a new age in future of technological advancement

Today, attention was drawn to the graphene a Nobel-Prize winning material that's tougher than diamonds and one of the most sougt after substance, at launch of the first wearable technology in Manchester. This "wonder" substance could well be an ecologically friendly, sustainable solution for an almost limitless number of applications. Graphene, occurs as a single thin tightly packed layer of carbon atoms that are bonded together in a hexagonal honeycomb lattice and carbon is the second most abundant mass within the human body and the fourth most abundant element in the universe. This makes carbon the chemical basis for all known life on earth,

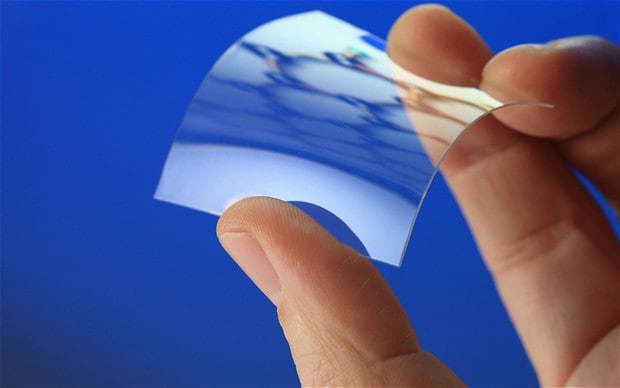

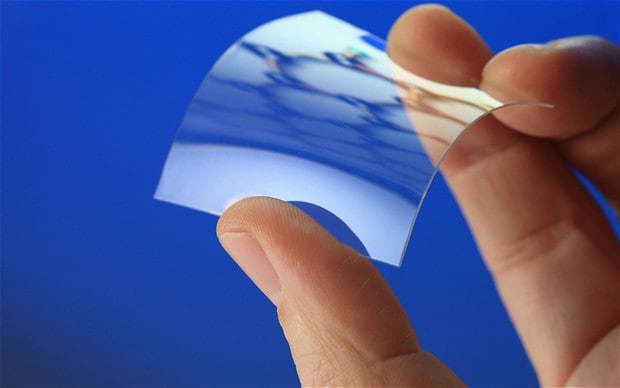

A future with graphene will give birth to clean drinking water for millions as graphene membranes could see huge progress in water purification technology in developing countries and provide more efficient desalination plants. Other breakthrough will include revolutionized electronics and energy storage through flexible, durable, semi-transparent mobile phones. Wearable technology, clothing that communicates, Electric sports cars and Lightweight planes. These are the future technologies which are becoming realistic in our present.

Model lights up the stage with the waorlds first graphene wearable technology at the manchester launch

Since its discovery or more accurately, the mechanical obtainment, researches have been carried out within different scientific disciplines. Outstanding discoveries have been made particularly in electronics and biotechnology, however this met a brickwall as graphene was not available for developmental research in commercial uses. This was because the creation of high quality graphene was a very expensive and involved a complex process involving the use of toxic chemicals to grow graphene as a monolayer by exposing Platinum, Nickel or Titanium Carbide to ethylene or benzene at high temperatures. Also, it was previously impossible to grow graphene layers on a large scale using crystalline epitaxy on anything other than a metallic substrate. This severely limited its use in electronics as it was difficult, at that time, to separate graphene layers from its metallic substrate without damaging the graphene.

However, studies in 2012 found that by analysing graphene’s interfacial adhesive energy, it is possible to effectually separate graphene from the metallic board on which it is grown, whilst also being able to reuse the board for future applications theoretically an infinite number of times, therefore reducing the toxic waste previously created by this process. Also, the quality of the graphene that was separated by using this method was sufficiently high enough to create molecular electronic devices successfully.

Recently, a team of scientists from the Commonwealth Scientific and Industrial Research Organisation (CSIRO) has potentially removed a major roadblock in commercial graphene production, developing a low-cost soybean-based graphene material that can be used by electronics manufacturers. In conjunction with researchers from The University of Sydney, University of Technology Sydney, and The Queensland University of Technology, CSIRO developed the novel "GraphAir" technology, that eliminates the need for a highly-controlled environment. Essentially, the technology grows graphene film in ambient air with a natural precursor, making its production faster and simpler.

Previously, graphene was purely grown in a highly-controlled environment with explosive compressed gases, requiring long hours of operation at high temperatures and extensive vacuum processing. GraphAir process for graphene fabrication is fast, simple, safe, potentially scalable, and integration-friendly.

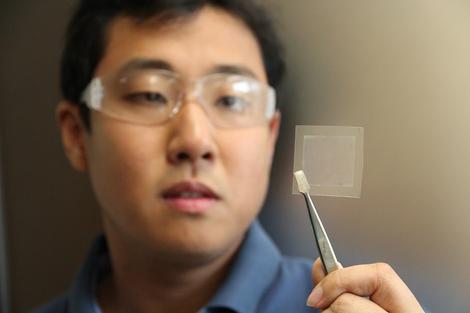

CSIRO scientist Dr Dong Han Seo holding a piece of graphene film Image: CSIRO

CSIRO scientist Dr Zhao Jun Han said. "Our unique technology is expected to reduce the cost of graphene production and improve the uptake in new applications." GraphAir transforms soybean oil into graphene films in one single step. Using heat, soybean oil breaks down into a range of carbon building units that are essential for the synthesis of graphene, the CSIRO explained.

Last year, researchers at MIT in the United States discovered that graphene could be used to slow light down below the speed of electrons to create an intense beam of light, paving the way for light-based circuits in ultra-compact computing devices. The research team explained that using light instead of flowing electrons to move and store data could push operating speeds up to vastly higher levels than those achieved by today's chips.

Although still theoretical, the discovery increases graphene's potential in computing chips. Scientists at IBM Research have been exploring how graphene can be used to create new chips that exploit the way electrons move faster through graphene than through other semiconductor materials. In addition, the CSIRO team also transformed other types of renewable and waste oil, such as those leftover from barbecues or cooking, into graphene films, allowing its application beyond electronics and to techniques used for water filtration and purification, renewable energy, sensors, and medicine all geared towards sustainable livelihood.